Efficient and safe warehouse operations rely heavily on the quality of material handling equipment. Among these, electric pallet jacks stand out as indispensable tools for moving heavy loads with ease. Choosing the right electric pallet jack is crucial to enhance productivity, reduce operator fatigue, and ensure seamless workflow within your facility.

At Hyworth Forklifts, we understand the unique challenges faced by warehouses in Sydney. With over a decade of experience, we specialise in providing high-quality electric pallet jacks tailored to meet diverse operational needs. Our commitment to excellence ensures that you receive reliable and innovative solutions that boost your warehouse efficiency. This guide will walk you through the essential factors to consider when choosing the right electric pallet jack, helping you make an informed decision that aligns with your business goals.

Understanding your warehouse needs

Assessing load capacity requirements

Choosing the right electric pallet jack begins with understanding the load capacity your warehouse demands. It’s essential to match the pallet jack’s capacity with the heaviest loads you handle regularly to ensure safe and efficient operations. Electric pallet jacks typically offer load capacities ranging from 1,500 kg to 3,000 kg. Assessing your maximum load requirements helps in choosing a model that can comfortably manage your toughest tasks without compromising performance or safety.

Moreover, considering future growth is vital. Opting for a pallet jack with a higher capacity than your current needs can accommodate increasing workloads, providing long-term value and flexibility for your warehouse operations.

Evaluating lift height requirements

Lift height is another critical factor when choosing the right electric pallet jack. Depending on your storage and stacking needs, the required lift height can vary significantly. Most electric pallet jacks are designed for low-level lifting, but some models offer enhanced lift capabilities to accommodate higher storage racks. Ensuring that the lift height of your pallet jack aligns with your warehouse’s vertical storage needs can optimise space utilisation and streamline your operations.

The lift height also affects how efficiently you can stack and retrieve pallets, directly influencing the overall productivity of your warehouse. Carefully evaluating your specific lift requirements will help you select a pallet jack that seamlessly integrates with your storage solutions.

Key features to consider when choosing the right electric pallet jack

Battery life and charging options

Battery life is pivotal for uninterrupted warehouse operations. Long-lasting batteries, such as lithium-ion, provide extended usage times and reduce the need for frequent recharging, enhancing productivity. Lithium-ion batteries are particularly advantageous as they offer faster charging capabilities, longer lifespans, and require minimal maintenance compared to traditional lead-acid batteries.

When choosing the right electric pallet jack, consider the battery’s capacity and how it aligns with your operational schedule. Models with quick charging features ensure that your equipment is ready for use with minimal downtime. Moreover, maintenance-free batteries can significantly lower operational costs and extend the lifespan of your pallet jacks, making them a smart investment for any warehouse.

Ergonomics and operator comfort

Operator comfort is essential for maintaining productivity and reducing fatigue during long shifts. Ergonomically designed electric pallet jacks feature adjustable handles, cushioned grips, and intuitive controls that enhance user experience. Adjustable handles allow operators of different heights to use the equipment comfortably, while easy-to-use controls simplify operation, making it accessible even for inexperienced users.

Moreover, reducing physical strain on operators not only improves efficiency but also minimises the risk of workplace injuries. Investing in pallet jacks that prioritise ergonomics ensures a safer and more comfortable working environment, contributing to overall warehouse efficiency.

Safety features

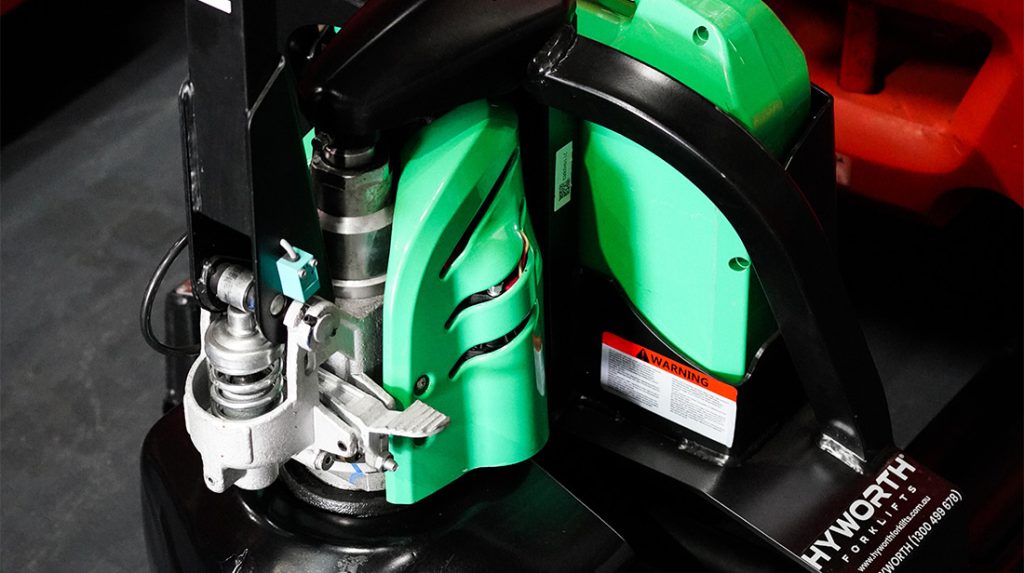

Safety should always be a top priority in warehouse operations. The right electric pallet jack comes equipped with essential safety features such as automatic braking systems, stability controls, and safety alarms. Automatic braking systems engage when the handle is released, preventing accidental movements and enhancing control. Stability controls, including anti-slip wheels and robust chassis designs, ensure the pallet jack remains steady even on uneven or slippery surfaces.

Safety alarms, such as overload warnings and proximity sensors, alert operators to potential hazards, reducing the risk of accidents. Additionally, features like emergency stopping and power braking further enhance operator safety, making electric pallet jacks a reliable choice for maintaining a secure warehouse environment.

Durability and reliability

Durability and reliability are critical factors when choosing the right electric pallet jack. High-quality materials and robust construction ensure that your pallet jacks can withstand heavy use and harsh conditions, reducing the need for frequent repairs and replacements. Selecting pallet jacks from reputable brands like Hyworth Forklifts guarantees dependable performance and longevity.

Moreover, considering warranty and after-sales support is essential for protecting your investment. Hyworth Forklifts offers comprehensive warranties and exceptional customer support, ensuring that any issues are promptly addressed. This commitment to quality and reliability ensures that your electric pallet jacks remain efficient and operational, providing long-term value for your warehouse.

Warehouse size and layout considerations

Maneuverability in tight spaces

The maneuverability of your electric pallet jack is crucial, especially in warehouses with narrow aisles and tight spaces. A tight turning radius allows for easy navigation through confined areas, enhancing operational efficiency and reducing the time spent on moving loads. Compact models are ideal for smaller warehouses where space is limited, ensuring that your pallet jacks can operate smoothly without causing disruptions.

Choosing a pallet jack with excellent maneuverability improves workflow and minimises the risk of collisions and accidents in crowded warehouse environments. Assessing the layout of your warehouse and selecting a pallet jack that can easily maneuver within your specific space constraints is essential for maintaining a seamless and efficient operation.

Adapting to warehouse layout

The layout of your warehouse significantly impacts the type and size of electric pallet jack you should choose. Factors such as aisle width, storage rack height, and the overall configuration of your storage areas determine the suitability of different pallet jack models. Customising pallet jack features to fit your specific warehouse layout ensures optimal performance and efficiency.

For instance, high-density storage environments may benefit from pallet jacks with extended lift heights and enhanced stability, while warehouses with wide aisles can accommodate larger models with greater load capacities.

Manual vs. electric pallet jacks

Benefits of electric pallet jacks

Electric pallet jacks offer numerous advantages over their manual counterparts, making them a preferred choice for many warehouses. Enhanced efficiency is a key benefit, as electric models can move heavier loads with ease, reducing the time and effort required for material handling tasks. This increased efficiency leads to higher productivity and smoother warehouse operations.

Additionally, electric pallet jacks significantly reduce operator fatigue, especially during long shifts or high-volume tasks. The motorised lifting and movement capabilities allow operators to handle heavy loads effortlessly, improving overall workflow and job satisfaction. Suitable for high-volume and heavy-duty operations, electric pallet jacks are an excellent investment for warehouses looking to boost their material handling efficiency and operational performance.

When to consider manual pallet jacks

While electric pallet jacks offer numerous benefits, manual pallet jacks remain a viable option for certain situations. They are more cost-effective, making them ideal for smaller operations or businesses with limited budgets. Manual models are also simpler to use and maintain, requiring less technical knowledge and fewer maintenance resources compared to electric counterparts.

In scenarios where heavy lifting is infrequent or the warehouse layout is straightforward, manual pallet jacks can effectively meet material handling needs without the additional investment in electric models.

Selecting the right fork length and width

Matching the fork length and width to your pallet sizes is essential for ensuring stability and handling efficiency. Properly sized forks provide balanced support, preventing pallets from slipping or tilting during movement. Standard pallet dimensions in your warehouse should guide your selection, ensuring that the forks can fully accommodate the pallets without any handling difficulties.

Incorrect fork dimensions can lead to operational inefficiencies and increased risk of accidents. Forks that are too short may not provide adequate support, while those that are too wide can make maneuvering cumbersome. Ensuring compatibility with the pallet sizes used in your warehouse enhances the overall functionality of your electric pallet jack, contributing to safer and more efficient material handling processes.

Considering the flooring and environment

The flooring and environment of your warehouse play a significant role in selecting the right electric pallet jack. Smooth, even surfaces are ideal for most pallet jacks, allowing for seamless movement and reducing wear on the equipment. However, if your warehouse has uneven or rough terrain, opting for pallet jacks with larger, more durable wheels is essential to maintain stability and performance.

Specific environments such as cold storage or outdoor areas require pallet jacks designed to withstand harsh conditions and temperature fluctuations.

Hyworth Forklifts: Your partner in choosing the right electric pallet jack

Hyworth Forklifts is your trusted partner in selecting the right electric pallet jack for your warehouse needs. Our extensive product range features state-of-the-art electric pallet jacks designed for durability, efficiency, and operator comfort. With over a decade of experience in the Australian market, we provide tailored solutions that align with your specific operational requirements.

Our commitment to excellence extends beyond product sales, offering comprehensive after-sales support and maintenance services to ensure your equipment remains in optimal condition. Contact Hyworth Forklifts today to explore our selection and receive personalised assistance from our team of experts, to help you choose the perfect electric pallet jack to enhance your warehouse operations.

Conclusion

Choosing the right electric pallet jack is a pivotal decision that can significantly impact the efficiency, safety, and productivity of your warehouse operations. By carefully assessing your warehouse needs, evaluating key features, and considering factors such as load capacity, lift height, and warehouse layout, you can make an informed choice that aligns with your business goals. Hyworth Forklifts is dedicated to providing high-quality, reliable electric pallet jacks backed by exceptional support and service. Visit our website or contact our experts today to find the perfect electric pallet jack for your warehouse, and take the first step towards enhanced operational efficiency and success.