Regarding material handling, forklifts are vital in ensuring that goods are moved safely and efficiently. Choosing the right forklift is essential to maintaining a smooth operation, whether you’re managing a warehouse or handling heavy outdoor loads. Two of the most commonly used forklift types are counterbalance forklifts and reach trucks.

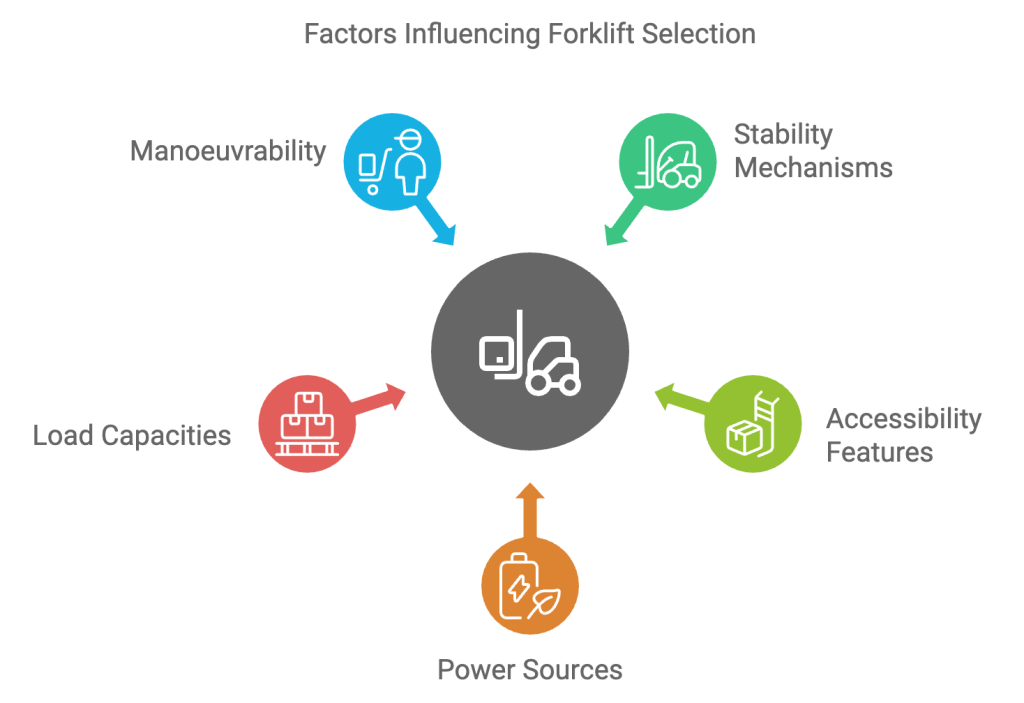

This blog post provides a detailed comparison of counterbalance forklifts vs reach trucks, helping you understand the key differences and advantages of each type. While both forklifts are designed to lift and move goods, their functionality, environment, and load capacities vary significantly. Understanding these differences will enable you to make an informed decision when selecting the right forklift for your business.

Whether you need to transport heavy loads across rough terrain or reach high shelves in tight warehouse aisles, knowing when to use a counterbalance forklift versus a reach truck is crucial for improving productivity and safety.

What are counterbalance forklifts?

Counterbalance forklifts are one of the most widely used types of forklifts in various industries. They get their name from the large counterweight located at the back of the machine, which helps to balance the load being lifted at the front. This counterweight prevents the forklift from tipping over when carrying heavier items.

These forklifts are designed to handle heavier loads efficiently and are often used in environments where stability is key. Whether it’s moving pallets in a warehouse or transporting materials across an outdoor worksite, counterbalance forklifts excel in both indoor and outdoor settings.

Their simple, straightforward design allows operators to drive up to the load, lift it, and move it without the need for complex adjustments. Thanks to their flexibility and power, counterbalance forklifts are commonly found in distribution centres and large manufacturing plants, where transporting heavy goods is a daily requirement.

What are reach trucks?

Reach trucks are specialised forklifts designed to operate in tight spaces, specifically in warehouses where high shelves and narrow aisles are common. Unlike counterbalance forklifts, which use a large counterweight for stability, reach trucks feature stabilising legs and an extended chassis. This design allows them to reach high shelves while remaining stable, even in confined spaces.

One of the main advantages of reach trucks is their ability to extend their tynes forward to access goods stored in tall racking systems, making them ideal for high-reach applications. This feature is particularly useful in warehouses where space is limited, and efficient use of vertical storage is essential.

Primarily used indoors, reach trucks are perfect for tasks where manoeuvrability and precision are needed. With their smaller wheels and low ground clearance, they are not suited for outdoor environments but are perfect for efficiently moving goods in warehouses.

Comparing stability mechanisms in counterbalance forklifts vs reach trucks

When comparing counterbalance forklifts vs reach trucks, one of the key differences lies in how they stabilise their loads. Counterbalance forklifts rely on a heavy counterweight located at the rear of the vehicle. This counterweight ensures that the forklift remains balanced when lifting heavier loads at the front, providing excellent load stability.

On the other hand, reach trucks use a different system to stabilise their loads. Instead of a large counterweight, they have stabilising legs that extend from the front of the truck. These legs, combined with the weight of the battery, help keep the forklift stable while lifting loads to great heights in narrow aisles. This makes reach trucks ideal for high-reach applications where precision and stability are critical.

Choosing the right forklift depends on the specific tasks at hand. If you need to lift heavy loads in open spaces or outdoors, a counterbalance forklift with its reliable balancing system is the better choice. However, for indoor environments with tall racks and tight spaces, reach trucks offer better manoeuvrability and stability, making them the preferred option for warehouse operations.

How reach trucks access goods beyond front racking

One of the key advantages of reach trucks is their ability to extend their tynes forward, allowing them to access goods stored in deeper racks. This feature is particularly useful in warehouses with double-deep racking, where space is maximised by storing pallets behind one another. The tynes on a reach truck can extend and retract, giving it the flexibility to easily reach goods that are stored beyond the front row of racks.

In contrast, counterbalance forklifts are limited in this regard. Their tynes are fixed, which means they can only lift goods directly in front of them. Without additional attachments like tyne extensions, counterbalance forklifts are unable to access pallets stored in deeper shelving units.

For businesses using double-deep or high-density storage systems, reach trucks are the ideal choice for optimising accessibility in warehouses and improving operational efficiency.

Different power sources for counterbalance forklifts and reach trucks

One of the key differences between counterbalance forklifts vs reach trucks is the range of fuel options available. Counterbalance forklifts are versatile in this regard, offering a variety of fuel types, including LPG (liquefied petroleum gas), diesel, and electric models. This flexibility allows businesses to choose the most suitable power source depending on their operational needs.

In contrast, reach trucks are typically powered by electricity. These electric forklifts are ideal for indoor environments, as they produce no emissions and are quieter in operation. Their reliance on batteries makes them perfect for warehouses, where clean air and noise reduction are essential.

Heavier lifting vs higher reach: Key differences in load capacity

When comparing counterbalance forklifts vs reach trucks, one of the most significant differences is in their lifting capacity and height capabilities. Counterbalance forklifts are designed to lift much heavier loads, making them ideal for industries that require heavy-duty lifting. For example, Hyworth Forklifts 2.5T Electric Counterbalance Forklift is capable of lifting loads up to 2.5 tonnes, making it a reliable choice for handling bulk materials.

In contrast, reach trucks are perfect where height and manoeuvrability are crucial. Hyworth Forklifts 1.6T Reach Truck can lift loads up to heights of 9 metres, offering exceptional performance in high-reach applications. Although reach trucks have a lower lifting capacity than counterbalance models—typically around 1.5 to 2.5 tonnes—their strength lies in their ability to access tall racking in narrow warehouse aisles.

For businesses handling heavy tasks, a counterbalance forklift like Hyworth’s electric range offers the necessary power and stability. However, for warehouses that need to optimise vertical storage, reach trucks like the 1.6T Reach Truck provide the height and precision needed for efficient operations.

Comparing turning radius and manoeuvrability for tight aisles

Counterbalance forklifts typically require more room to manoeuvre because of their larger turning radius. These forklifts are designed for more open areas, making them less suited to working in confined spaces like narrow warehouse aisles.

On the other hand, reach trucks excel in environments where space is limited. With a smaller turning radius, reach trucks are designed to navigate tight aisles and confined warehouse spaces efficiently. Their compact design and ability to make sharp turns allow them to work seamlessly in narrow racking setups. This makes reach trucks an ideal choice for operations where manoeuvrability is key, particularly in busy or space-constrained warehouses.

If your operations require frequent use in tight areas, reach trucks offer the manoeuvrability needed to maintain efficiency in tight spaces.

Which forklift type suits your needs best?

In summary, the choice between counterbalance forklifts vs reach trucks depends on your specific operational needs. Counterbalance forklifts are ideal for handling heavier loads, especially in open spaces, while reach trucks excel in reaching higher racks and navigating narrow aisles with ease. Each forklift type serves a distinct purpose, so selecting the right one will improve both efficiency and safety.

If you’re unsure which forklift is best suited for your business, contact Hyworth Forklifts for expert advice. Our team can help you choose the perfect solution for your material handling needs.